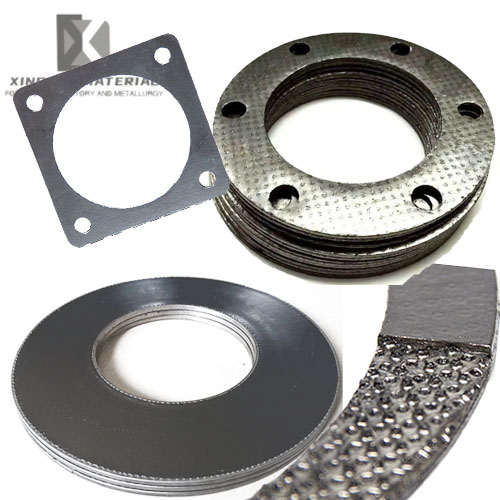

Flexible Graphite gasket with tanged metal sheet

Graphite Laminate with SS304/316 Foil Insert

Graphite Laminate with SS304/316 tang Insert

Graphite Laminate with Tinplate tang Insert

Graphite Laminate with Polyester Insert

Graphite Laminate with with SS304/316 mesh Insert

Flange Graphite Gasket

Manufacturer's customized graphite composite gasket, reinforced graphite gasket, high-strength graphite gasket, full specification

Description:

Graphite composite gaskets, also known as reinforced graphite gaskets or high-strength graphite gaskets, are made by punching or cutting reinforced graphite plates. They have good corrosion resistance, high/low temperature resistance, good compression resilience, and high strength. Widely used in Flange sealing.

Model And Technical Data:

DN 10-40 too small to wrap the edge, it is It is a direct cutting with slightly processed edges

DN50-DN200 We suggest use the standard wrapped the edge.

Laminated Material | Compressive Strength | Temperature ℃ | Compression Ratio(%) | Resilience(%) | |

No-Oxygen | In an oxidized state | ||||

ST Carbon Steel Tanged plate | ≥4.8 | -10-450 | -10-550 | 30-35 | 15-20 |

SS304,SS316 Tang Foil | ≥4.8 | -240-450 | -200-600 | 30-35 | 15-30 |

SS304,SS316 Plain Foils | ≥4.8 | -240-450 | -200-600 | 30-40 | 10-15 |

SS304 Mesh Sheet | ≥4.8 | -240-450 | -200-600 | 40-50 | 15-20 |

Reinforcement Material | Air Permeability (cm3/min) | Sealing | Sealing Constant | ||

N2 m1/hr | Bumming oil A | "M" | "Y" | ||

ST Carbon steel Tanged Insert | <=0.8 | 30 | <0.5 | 3.0 | 9000 |

SS304,SS316 Tanged Foil | <=0.8 | 60 | <0.5 | 2.5 | 4000 |

SS304,SS316 Flate Foil | <=0.4 | 35 | <0.5 | 2.0 | 900 |

Ss304, Mesh Sheet | ≥1.0 | 70 | <0.5 | 3.0 | 5000 |

Physical Data sheet :

Items | Density Tolerance | C % | Tensile Strength | Sulfur % | %Chloride | Stress Relaxation % | Loss on Ignition % |

Industrial | ±0.06g/cm | ≥98 | 4 Mpa | <1000ppm | <50ppm | 10 | 2.0≤ |

Nuclear | ±0.05 g/cm | ≥99.5 | 5 Mpa | <700ppm | <35ppm | 10% | 0.5≤ |

Reinforced Graphite Gasket Service Technical Data :

Gasket Factory | m=2 |

Gasket Service Pressure | ≤10MPa |

Gasket Service Temperature | -196℃-650℃ |

Minimum Tight compression ration | y=30MPa |

Customers choose different reinforcement materials according to different operating conditions, and special materials can be requested.

We can provide any standard or non-standard dimensions, including ASME, DIN, JIS, GB, and other standards. We can provide irregular shapes such as round and square, and can also provide reinforced strip and inner and outer edge metal corrugated composite gaskets as needed..

The maximum processing size of reinforced graphite gaskets is unlimited, and special specifications or various non-standard products can be formulated according to customer requirements.

Raw Material:

The Commonly used inner layer reinforcement materials for reinforced graphite gaskets include SS304,SS316, or Tinplate, with a thickness of 0.1mm-0.127mm.

They come in the forms of Punching plate reinforcement, Mesh plate reinforcement, and Plain plate reinforcement.

The popular and widely used is SS 304 reinforced graphite gasket ( SS304 0.1mm Tanged Insert)

Application:

Various shape or circular geometric gaskets can be made and widely used in :

ü Pipelines

ü Valved

ü Pumps

ü Pressure vessels

ü Heat exchangers

ü Condensers

ü Generators

ü Air compressors

ü Exhaust Pipes

ü Refrigeration machines

ü Graphite reinforced gasket can also be cut into complex shaped gaskets as your DRAWINGS, Such as water level gauge gaskets, perforated flange gaskets, and cylinder gaskets for automotive diesel engines

Can replace asbestos and rubber gaskets and iron clad gaskets.

Types of reinforced graphite gaskets

High strength graphite gaskets can be processed into the following forms according to usage needs:

1. Basic graphite composite gasket

2. Wrapped with inner reinforced graphite gasket.

3. Wrapped with outer reinforced graphite gasket.

4. Wrapped with inner and outer reinforced graphite gasket.

(Note: The edge wrapping form of reinforced graphite gasket not only maintains the excellent performance of the original gasket, but also facilitates installation and disassembly, is not easily damaged, and can also prevent medium erosion of the gasket, improving pressure resistance. The commonly used edging materials are 304 or 316 stainless steel. )