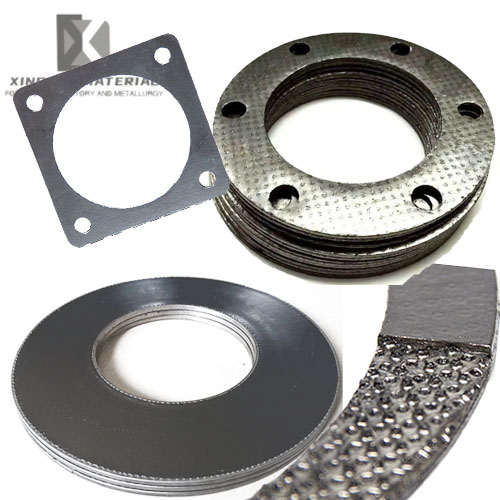

Expansion PTFE Sealing Gasket

Made of polytetrafluoroethylene resin (PTFE), pressed by molds and sintered.

Tetrafluoroethylene gasket: the full name of PTFE gasket is also called PTFE gasket or Teflon gasket abroad.

Flat gaskets, V-shaped gaskets, piston rings, ball valve gaskets, etc., which are made of PTFE rods, tubes, and plates by mechanical turning or cutting, have good characteristics such as corrosion resistance, aging resistance, and non-conductive. Polytetrafluoroethylene has a pH value of 0-14 (excluding molten alkali metals and fluorine under high temperature and pressure). It can have good mechanical strength between -100 ℃ and 100 ℃.

Description:

Types:

l Pure PTFE gasket

l PTFE clamp gasket

l Expanded PTFE gasket

l Modified filled PTFE gasket

1、 Pure PTFE gasket

It is a flat gasket, V-shaped gasket, piston ring, ball valve gasket, etc. made of PTFE rod, tube and plate by mechanical turning or cutting, which has good characteristics of corrosion resistance, aging resistance and non-conductive.

Polytetrafluoroethylene has a pH value of 0-14 (excluding molten alkali metals and fluorine under high temperature and pressure). It can have good mechanical strength between -100 ℃ and 100 ℃. Pressure 10Mpa.

Attention: When the temperature is below -185 ℃. PTFE gaskets will become brittle. Pure polytetrafluoroethylene gasket is a clean sealing product, which will not pollute any substances it contacts. It can be widely used in food, medicine and other industries. Flat gaskets, V-shaped gaskets, piston rings, ball valve gaskets, etc., which are machined or cut, have good characteristics such as corrosion resistance, aging resistance and non-conductive.

Production process

1) Preparation of raw materials; Ingredients: Pure F4 product, raw material F4 fine resin, crushed, sieved

2) Mold preparation: Wipe clean with alcohol, and there is no rust or attachment inside the mold

3) Weighing, according to the formula G=PV (where G is the amount of material added and P is the density of the prefabricated product (2.18g/cm3)

Weigh the product (V is the volume of the product).

4) Feeding: Evenly distribute F4 resin throughout the entire pressing surface.

5) Prefabrication (pressing): Calculate the gauge pressure of the press according to the formula, and set the gauge pressure of the press. Perform suppression

6) Demolding and trimming: Take out the semi-finished product from the mold, trim its surface to make it flat and the edges neat. Prepare for molding.

7) Sintering: Slowly place the semi-finished product into the sintering furnace, add an appropriate amount, heat it up for about one hour to 390 degrees, and then keep it warm for another hour. After about four hours of molding, start cooling. After reaching the indoor temperature, the finished product is discharged from the furnace, and finally the shaping is completed.

2、 PTFE clamp gasket

It is composed of soft pads such as asbestos rubber sheets or asbestos free sheets and polytetrafluoroethylene coated thin sheets. The V-shaped (cut type) PTFE clamp gasket is mechanically turned from PTFE sheets, while the U-shaped (folded type) PTFE clamp gasket is made by heating and bonding the edges of PTFE tape. It has excellent corrosion resistance and good compression rebound rate, and is widely used in sealing various strong acids, strong alkalis, strong oxidation, chlorine gas, and non polluting media. Usually suitable for medium and low pressure areas.

3、 Expansion PTFE sealing gasket

Due to this special property, expanded PTFE gaskets are more suitable for narrow sealing surfaces and sealing equipment with a certain requirement for gasket width. Expanded PTFE gaskets have most of the advantages of polytetrafluoroethylene gaskets, but they do not have issues with creep and cold flow. The sealing performance of expanded PTFE gaskets is not only very reliable, but also has characteristics such as sealing, high temperature resistance, and anti explosion. Therefore, it is superior to other PTFE plate shaped gaskets. The expanded PTFE gasket itself is an ideal choice under flange conditions due to its stable size and good compliance. It can not only adapt to rough surfaces, but also be compressed into very tight gaskets, making the seal tighter and more durable.

4、 Graphite filled PTFE gasket

Also known as graphite modified PTFE gasket or black PTFE gasket, it is made by adding a certain amount of filler, such as glass fiber, bronze powder, molybdenum disulfide, graphite, carbon fiber, etc., to polytetrafluoroethylene resin. After high-speed mixing, it is molded and then sintered at high temperature., Has excellent compressibility, resilience, and sealing properties. Its unique properties and advanced features demonstrate sealing and torque retention. In terms of cold flow and material creep characteristics, it overcomes the shortcomings of traditional PTFE, and at the same time, it can better maintain bolt load than traditional PTFE, which not only improves the durability of sealing but also reduces flange maintenance. Advantages of graphite filled PTFE gaskets: low friction coefficient, good compression strength, and improved wear resistance; This greatly exceeds the use of traditional PTFE, which not only improves the environment but also saves costs. Suitable for chemical, petrochemical, hydrocarbon reactions, and power plants.