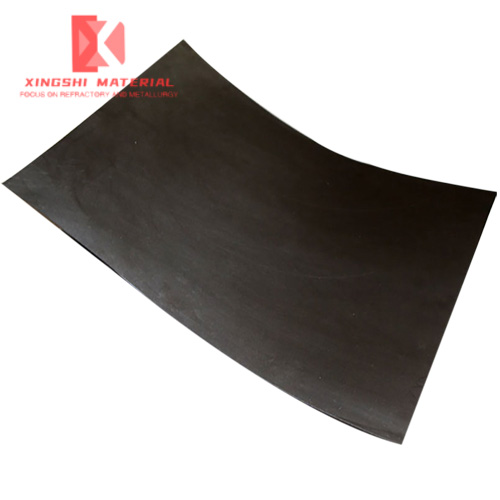

Products Description

Flexible graphite Sheet, Graphite Foil, Graphite paper, Graphite Tape, Graphite Strip (paper)

Flexible graphite material, also known as flexible graphite paper or flexible graphite sheet, is made of natural graphite flakes after chemical treatment and then heated to high temperature to form graphite worms. The density of this worm-like graphite powder is about 0.003g/cc. Then the flexible graphite coil is formed by rolling. The expanded graphite coiled material does not contain binder and filler, so it has high purity, good corrosion resistance, radioactivity resistance, high/low-temperature resistance, good compression resilience, self-lubrication and impermeability, and is suitable for sealing low-pressure parts. Graphite coil and metal sheet can be compounded into various forms of graphite composite plate.

What is a graphite sheet?

Graphite sheet provides superb sealing properties for high temperature, high-pressure transfer of gases, liquids, steam, chemicals and corrosives. In high purity high crystal natural graphite flakes are produced which are processed into constant foils under special acid and thermal treatments. Fuel cell companies use this material as a separator layer on solid wastes and gaseous wastes. The expanded graphite crystals are then deposited into foil in a calendaring process without any resins and binders.

Product application:

1. it can be used as graphite packing ring material

2. it can be combined with metal sheet to form a graphite composite sheet and cut into sealing gaskets of various shapes

3. it is directly used to make various low-pressure gaskets or high-temperature insulation pads after being processed into thick plates

Common specifications of graphite sheet :

Width 1000mm or 1500mm, coil length 30,50,80m; Plate 1000mm or 1500mm; Coil thickness 0.15-1.0; Plate 1.0mm-5mm;

Density, 0.8-1.25g/cm3, other special specifications can be requested by customers.

Item | Standard Value |

C concentration | 99% |

S concentration | <1000ppm |

chlorine concentration | <45ppm |

tensile strength | 4.5MPa |

compressibility | >40% |

recovery | >10% |

Temperature | -200ºC-600ºC |

Pressure | 20MPa |

Terence of Thickness | -0.04mm~+0.04mm |

Terence of Dimension | In accordance with your Gasket size |

Terence of Density | -0.06~g/cm3+0.06gcm3 |

Grades Separate :JB/T53392-1999

Mechanical Data | Qualified product | Top Grade | Superior Grade | |

Density Tolerance | <0.4 | ±0.10 | ±0.05 | |

≥0.4 | ±0.07 | |||

Tensile Strength MPa | ≥3.2 | ≥4.5 | ≥5.0 | |

Compression Ratio % | 35~55 | |||

Rebound Rate % | ≥9 | ≥11 | ≥12 | |

Stress relaxation rate % | ≤10 | |||

Ash % | ≤6.0 | ≤3.0 | ≤1.0 | |

Heat loss on ignation % | 450ºC | ≤1.0 | ≤0.5 | |

600ºC | ≤20 | ≤15 | ||

Sulphur content | ≤1500ppm | ≤1000ppm | ≤600ppm | |

Chloride content | ≤100ppm | ≤50ppm | ≤20ppm | |

Product Features :

Performance characteristics of graphite Sheet , Graphite Tape , Graphite Paper :

1. Excellent heat resistance and cold resistance. Flexible graphite has almost no change in physical properties from an ultra-low temperature of -270 ° C to a high temperature of 3650 ° C (in non oxidizing gas), and it can also be used to about 450 ° C in air;

2. Excellent chemical corrosion resistance. Flexible graphite is corrosion resistant to almost all inorganic and organic media except in aqua regia, concentrated nitric acid, concentrated sulfuric acid, high-temperature dichromate, potassium permanganate, ferric chloride and other strong oxidizing media;

3. Good self lubrication. Flexible graphite, like natural graphite, is easy to slide between layers under the action of external force, so it has lubricity, good wear reduction and low friction coefficient;

4. High rebound rate. When the shaft or shaft sleeve has radial circular runout due to eccentricity in manufacturing and installation, it has sufficient floating performance, and it can be well sealed even if the graphite cracks, so as to ensure tight fitting and prevent leakage.

5. The expanded graphite gasket does not have high requirements on the flange surface. A small pre tightening force can achieve the sealing effect. It is easy to cut. It is an economical and practical gasket.

Work For :

It is widely used in dynamic and static sealing of machines, pipes, pumps and valves in electric power, petroleum, chemical industry, instrument, machinery, diamond and other industries. It is an ideal new sealing material to replace traditional seals such as rubber, fluoroplastic and asbestos. It can also be used in smart phones, mid mobile Internet devices, tablets, notebooks, led liquid crystal displays, PDP plasma TVs, LED lighting and backlight modules, digital cameras, digital cameras, projectors and so on.

The foreign manufacturing standards for metal wound gaskets are: ASME B 16.20, ASME B 16.5, ASME B 16.47 A (B), BS EN1092, JIS, and NF, etc. and can provide various kinds of winding pad graphite tapes as needed, and the winding mat asbestos is not available. Asbestos tape, wound mat ceramic fiber tape, metal formed steel strip, etc.

Wrapped pad graphite tape related standard status:

HG20610-2009 Wound gasket for steel pipe flanges European system of Ministry of Chemical Industry

HG20631-2009 Wound gasket for steel pipe flanges

GB/T4622.2-97 Wound gaskets Gaskets for pipe flanges National standard

JB/T4719-92 Winding gasket for shell and tube heat exchanger

JB/T90-94 Wound gasket for pipe flanges

JB/T4705-2000 Wound gasket for pressure vessel flanges

SH3407-96 Wound gasket for pipe flange

JB/T 53392-1999|Flexible Graphite Sheet Product Quality Grading

B/T 7758.2-2005|Flexible graphite plate Technical conditions

JB/T 9141.4-1999|Flexible graphite sheet, compression rate, rebound rate test method

JB/T 7758.4-2008|Flexible graphite sheet Determination of chlorine content

JB/T 7758.3-2005|Method for determination of sulfur content in flexible graphite sheets

Products Display :

Package :

Export Standard : Cartons ON wooden Pallets , If afraid damage , Wooden Case is Acceptable . Or Customized .

Welcome to Xingshi Carbon ! We are Graphite Paper Factory , Not sealing Material Trader !!!