Application of Powder Metallurgical Graphite

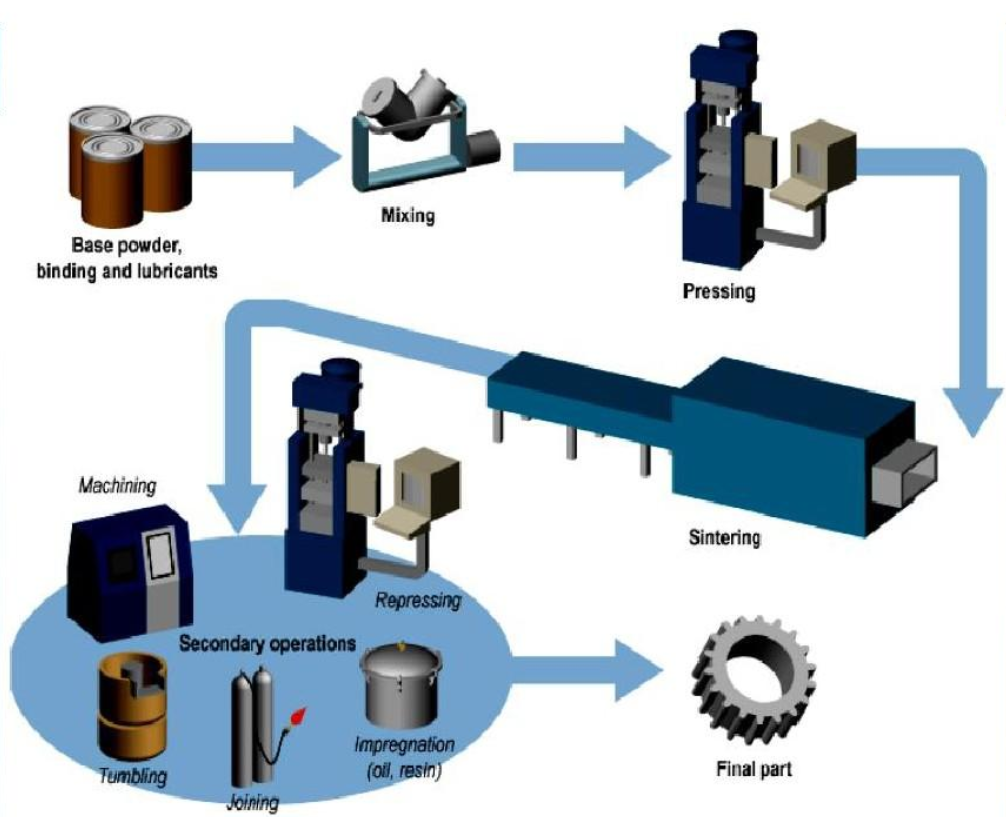

Powder metallurgy is a technology that uses metal or non-metal powders as raw materials to manufacture parts and products

through a series of processing methods. Graphite is a common material with extensive applications in powder metallurgy.

This article will elaborate on the characteristics of graphite, its use in powder metallurgy, and related development trends.

1、 The application of graphite in powder metallurgy

Graphite is a very important additive with extensive applications in powder metallurgy. Powder metallurgy technology can obtain

finished products by pressing metal powder into the desired shape and then high-temperature sintering. In this process,

the addition of graphite can play the following roles:

1. Improve wear resistance

Due to its self-lubricating properties, graphite can form a lubricating film on the surface of solid materials, thereby improving

their wear resistance. This coating can effectively reduce friction and wear between materials, making them more durable.

2. Improve hardness

Graphite can be introduced into the grain boundaries of materials, thereby promoting their diffusion and activity. This is beneficial

for improving the grain boundary strength of the material and improving its hardness and toughness.

3. Improve conductivity

Graphite has excellent conductivity and can be added as a conductive agent to metal materials to improve their conductivity.

4. Improve lubrication

Due to its self-lubricating properties, graphite can be added as a lubricant to metal materials, thereby improving their lubrication

performance.

The advantages of graphite in powder metallurgy

The application of graphite in powder metallurgy has the following advantages:

It can improve the performance of materials

Graphite can improve the wear resistance, hardness, conductivity, and lubrication performance of materials, thereby increasing

their service life and performance.

Can reduce material costs

Graphite is a relatively inexpensive additive, and adding graphite can reduce material costs.

It can improve production efficiency

Powder metallurgy technology has the advantages of high production efficiency and low material loss. Adding graphite can

further improve production efficiency and reduce production costs.

3、 Summary

Graphite, as an excellent additive, has a wide range of applications in powder metallurgy. By adding graphite, not only can the

performance of the material be improved, but also costs can be reduced and production efficiency can be improved. Therefore,

graphite is a very important material in powder metallurgy and should receive more research and application.

Graphite can also be used to prepare thermal conductive materials. Due to the excellent thermal conductivity of graphite, materials

prepared by mixing graphite powder with metal powder exhibit excellent thermal conductivity. This material is widely used in

electronic products, cooling systems, heat exchangers and other fields, which can effectively improve heat dissipation efficiency

and protect the normal operation of equipment.

With the advancement of technology and continuous improvement of processes, the application of graphite in powder metallurgy

is also constantly developing. On the one hand, the nanomaterialization and modification of graphite have become a hot research

topic. Nanographite has a larger specific surface area and better conductivity, which can play a better role in composite materials,

self-lubricating materials, and other fields. On the other hand, the two-dimensional structure of graphite has also attracted the

attention of researchers. Two dimensional graphite has a special electronic structure and optical properties, and is widely used in

fields such as electronic devices and energy storage materials.

Graphite has important applications in powder metallurgy. It can be used to prepare composite materials, self-lubricating materials,

and thermal conductive materials, improving the performance and function of materials. With the advancement of technology,

the application of graphite in powder metallurgy is also constantly developing. Researchers are exploring methods for nanoscale

and two-dimensional graphite in order to further improve the performance and functionality of materials. I believe that

in the near future, the application of graphite in powder metallurgy will be more widely developed and applied.